AI Terminal

Greatland Resources Limited

Earnings Release • Nov 27, 2025

10491_rns_2025-11-27_431b86ce-025c-44cf-8ff7-0026e51e40e7.html

Earnings Release

Open in ViewerOpens in native device viewer

National Storage Mechanism | Additional information ![]()

RNS Number : 2579J

Greatland Resources Limited

27 November 2025

Greatland Resources Limited

Greatland Resources Limited

W: https://greatland.com.au

: x.com/greatlandgold

: x.com/greatlandgold

NEWS RELEASE | 27 November 2025

West Dome Underground Project Update

THIS ANNOUNCEMENT CONTAINS INSIDE INFORMATION AS STIPULATED UNDER THE UK MARKET ABUSE REGULATIONS. ON PUBLICATION OF THIS ANNOUNCEMENT VIA A REGULATORY INFORMATION SERVICE, THIS INFORMATION IS CONSIDERED TO BE IN THE PUBLIC DOMAIN.

West Dome Underground project continues to expand with ongoing drilling revealing a growing opportunity

Wide, high grade results from Western Stockwork Corridor, adjacent to the existing high grade Western Limb and Eastern Limb

Highlights

§ 19 holes for >9,000 metres completed from the West Dome Underground (WDU) Phase 2 drilling program, with results received from 9 holes. The drilling program has largely focused on growth drilling for H1 FY26, targeting the southern extension of mineralisation.

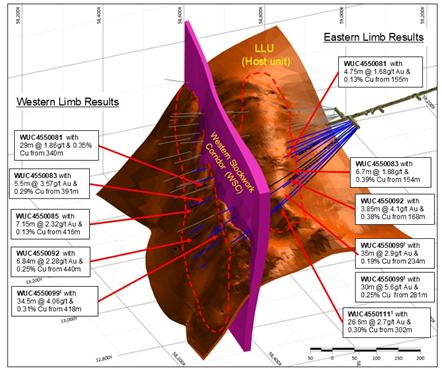

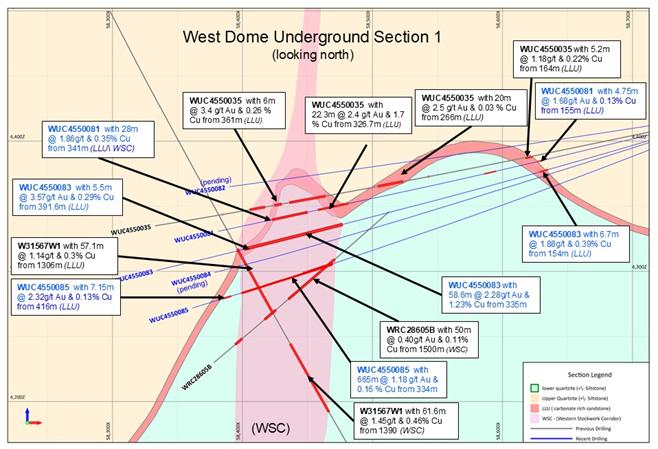

§ Increasing drill density has improved our understanding of the WDU, with three mineralised domains now confirmed: a broad sub-vertical Western Stockwork Corridor (WSC), flanked by the extensive Western Limb and Eastern Limb high grade shoots hosted within the Lower Limey Unit (LLU), an important geological horizon for gold-copper mineralisation at Telfer.

§ Recent drilling has returned exceptional drilling results in the WSC domain over a broad zone of stockwork mineralisation, with results across a large zone between 40-70m wide (true width) and over 200m down dip extent:

- 56.6m @ 2.24g/t Au & 1.26% Cu (127 gram-metres Au (gm)1) from 337m (WUC4550083)

- 82.2m @ 1.90g/t Au & 0.31% Cu (156gm) from 360.7m (WUC4550092)

- 66.5m @ 1.18g/t Au & 0.16% Cu (78gm) from 334m (WUC4550085)

- 24.0m @ 1.18g/t Au & 0.10% Cu (28gm) from 309m (WUC4550081)

- 22.5m @ 1.43g/t Au & 0.01% Cu (32gm) from 396m (WUC45500992)

§ In addition, high grade mineralisation continues to be intercepted within the LLU across both the Eastern Limb and Western Limb, with mineralisation on both limbs now over 500m in strike and remain open. The following significant results have been received to date:

Western Limb LLU

- 34.5m @ 4.06g/t Au & 0.31% Cu (140gm) from 418.5m (WUC45500992)

- 29m @ 1.86g/t Au & 0.34% Cu (54gm) from 341m (WUC4550081)

- 5.5m @ 3.57g/t Au & 0.29% Cu (20gm) from 389m (WUC4550083)

- 6.84m @ 2.28g/t Au & 0.25% Cu (17gm) from 440m (WUC4550092)

- 7.15m @ 2.32g/t Au & 0.13% Cu (15gm) from 416m (WUC4550085)

Eastern Limb LLU

- 35m @ 2.9g/t Au & 0.19% Cu (101gm) from 234m (WUC45500992)

- 30m @ 5.6g/t Au & 0.25% Cu (168gm) from 281m (WUC45500992)

- 26.6m @ 2.7g/t Au & 0.30% Cu (71gm) from 302m (WUC45501112)

- 6.7m @ 1.88g/t & 0.39% Cu (12gm) from 154m (WUC4550083)

- 3.85m @ 4.1g/t Au & 0.38% Cu (16gm) from 168m (WUC4550092)

§ Development and study work:

- Existing Telfer infrastructure supports the potential to accelerate a new mine at WDU, with the ability to utilise the existing Main Dome Underground (MDU) infrastructure that previously supported an underground mining rate in excess of 5Mtpa (Main Dome Underground mining rate currently approximately 1.2Mtpa).

- A pre-feasibility study is underway and will assess utilisation of the existing MDU infrastructure, including the existing ventilation system, underground haulage shaft and crusher system.

- Second development drive is approximately 60% of the distance to the current drilling location. Once complete, the second drive will provide significant optionality to further increase drilling activities and advance any early works.

§ A third diamond drill has been allocated to the West Dome Underground, to accelerate drilling and support delivery of a maiden Mineral Resource Estimate targeted for the March 2026 quarter.

Notes:

(1) Formula: gm = interval width multiplied by Au grade

(2) Result reported in the announcement "September Quarter Resource Development & Exploration Update" on 22 October 2025

Greatland Managing Director, Shaun Day, commented:

"We continue to see excellent drilling results and progress at the compelling West Dome Underground project.

"The Main Dome Underground began production almost 20 years ago and continues operating today, having produced more than 3 million ounces of gold to date. Our West Dome Underground drilling confirms that key geological units and mineralisation styles at the Main Dome Underground are present at the West Dome Underground, and continues to deliver high grades and excellent widths.

"Access to the West Dome Underground effectively opens access to a new quartile of the Telfer mine, being the two open pits and potentially the opportunity to start a second underground mine.

"Drilling to date has now identified three separate mineralised domains, the high grade Western Limb and Eastern Limb, and the wide sub-vertical Western Stockwork Corridor. Mineralisation remains open along strike and down dip. Given the impressive results to date, a third diamond drilling rig has been allocated to the West Dome Underground, which will further inform a targeted maiden Mineral Resource estimate in the March 2026 quarter.

"The second development drive to the West Dome Underground is well progressed, and a pre-feasibility study is now underway and will assess how the substantial existing infrastructure capacity at the Main Dome Underground can be leveraged to deliver a pathway to production."

Overview

Greatland Resources Limited (Greatland) is pleased to provide this update on the West Dome Underground project.

The FY26 WDU drilling program aims to continue to expand the mineralisation footprint while at the same time infilling existing drilling to an adequate spacing (40m x 40m) to support Mineral Resource estimation and subsequent mining studies to support a decision to mine.

Drilling has initially focused on the less drilled southern extent of the mineralised system, with results to date indicating an increase in grade and thickness within the Eastern Limb and sub-vertical WSC, while continuing to confirm the high-grade mineralisation seen within the Western Limb during previous drilling programs.

Drilling will progress northwards over the remainder of FY26, with a further 22,500m of drilling planned to continue to infill existing drilling along with testing vertical extent of the system (above and below the LLU).

The maiden Mineral Resource estimate is targeted in the March 2026 quarter. In the meantime, based on the impressive results to date a number of workstreams are underway to progress the potential development of the WDU as an additional high grade ore source.

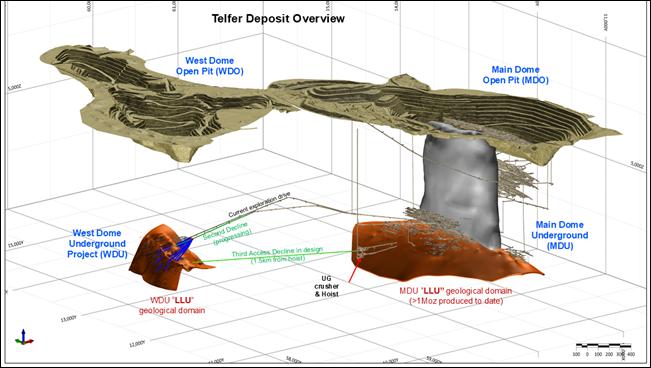

Figure 1: Telfer Deposit mine area Location Map

Drilling Results Discussion

Western Stockwork Corridor

The WSC mineralisation is located within the hinge of the WDU fold (Figure 2) and consists of a broad zone of concordant and discordant stockwork/sheeted and breccia veins, containing chalcopyrite, pyrite, white & pink dolomite, quartz and galena. There is also a notable overprinting of albite alteration.

The potential of this domain was first identified during the maiden underground drilling campaign, which although focused on the high-grade Western Limb also intercepted several broad zones of stockwork mineralisation within the hinge of the LLU fold with the following promising results:

§ 42.0m @ 1.97 g/t Au & 0.49% Cu (83gm) from 294.0m (WUC45500193)

§ 18.4m @ 3.93 g/t Au & 0.92% Cu (72gm) from 330.6m (WUC45500203)

§ 36.1m @ 2.14 g/t Au & 0.21% Cu (77gm) from 365.9m (WUC45500233)

§ 31.7m @ 1.34 g/t Au & 0.35% Cu (42gm) from 366.0m (WUC45500223)

§ 23.3m @ 1.64 g/t Au & 0.54% Cu (38gm) from 341.0m (WUC45500303)

Recent drilling to the south (Figure 2) has continued to return multiple intercepts of broad higher-grade mineralisation within the WSC, with the following significant results received:

§ 56.6m @ 2.24g/t Au & 1.26% Cu (127gm) from 337m (WUC4550083)

§ 82.2 @ 1.90g/t Au & 0.31% Cu (156gm) from 360.7m (WUC4550092)

§ 66.5m @ 1.18g/t Au & 0.16% Cu (78gm) from 334m (WUC4550085)

§ 24.0m @ 1.18g/t Au & 0.10% Cu (28gm) from 309m (WUC4550081)

§ 22.5m @ 1.43gt Au & 0.01% Cu (32gm) from 396m (WUC45500992)

The drilling to date confirms continuous WSC mineralisation over 700m of strike, averaging approximately 40m wide (true width) x 150m dip extent (height), and remains open along strike, and up and down dip. These recent results indicate higher grade and increased width to the south of the Phase 1 drilling.

The WSC is considered comparable to the Vertical Stockwork Corridor or 'VSC' domain that was one of the dominant domains targeted by the Sub-Level Cave (SLC) at the Telfer Main Dome Underground from 2008 to 2019 (mining approximately 5Mtpa on average) and is a key extension opportunity currently under assessment.

Note (3): Result reported in the Greatland Gold plc AIM announcement "West Dome Underground Project" on 20 February 2025

Western Limb

The Western Limb of LLU mineralisation has returned some of the highest grade WDU results to date, and continues to do so. Mineralisation has been confirmed over 700m in strike, averaging 10m wide and over 100m down dip to date, and remains open to the north and south.

The following recent significant results have been returned:

§34.5m @ 4.06g/t Au & 0.31% Cu (140gm) from 418.5m (WUC45500992)

§ 29m @ 1.86g/t Au & 0.34% Cu (54gm) from 366m (WUC4550081)

§ 5.5m @ 3.57g/t Au & 0.29% Cu (20gm) from 389m (WUC4550083)

§ 7.15m @ 2.32g/t Au & 0.13% Cu (17gm) from 416m (WUC4550085)

§ 6.84m @ 2.28g/t Au & 0.25% Cu (16gm) from 447m (WUC4550092)

Eastern Limb

The Eastern Limb mineralisation is hosted with the same LLU unit that has hosted the Western Limb and has been defined over 500m in strike, 100m dip extents and averaging 10m true width (Figure 2).

As reported in the announcement "September Quarter Resource Development & Exploration Update" on 22 October 2025, recent drilling results have returned higher grade mineralisation in this Eastern Limb as we have drilled to the south, with recent results returning similar grades to those seen in the Western Limb.

The following recent significant results have been returned:

§ 35m @ 2.9g/t Au & 0.19% Cu (101gm) from 234m (WUC45500991)

§ 30m @ 5.6g/t Au & 0.25% Cu (168gm) from 281m (WUC45500991)

§ 26.6m @ 2.7g/t Au & 0.30% Cu (71gm) from 302m (WUC45501111)

§ 6.6m @ 1.88g/t Au & 0.39% Cu (12gm) from 154m (WUC4550083)

§ 3.85m @ 4.1g/t Au & 0.38% Cu (16gm) from 168m (WUC4550092)

§ 4.75m @ 1.68g/t Au & 0.13% Cu (8gm) from 155m (WUC4550081)

§ 12.6m @ 1.39g/t Au & 0.13% Cu (17.5gm) from 209.4m (WUC4550102)

Figure 2: West Dome Underground "3D Isometric view" looking north

Figure 3: West Dome Underground Geological Type Section

Main Dome Underground infrastructure

The MDU is situated below the Main Dome Open Pit, and to date has mined over 75Mt of ore, for more than 3.1Moz gold and 210kt copper.

In 2007, construction of a 6Mtpa capacity underground crusher, dual conveyor, shaft and hoist was completed and has been in continuous use since then. The MDU mainly operated as a sub level cave from 2008 to 2019, extracting on average 5Mtpa, before the mine moved to long hole open stoping.

Currently the Main Dome Underground is operating at a mining rate of approximately 1.2Mtpa. Accordingly, there is significant available infrastructure capacity at the MDU to support potential mining operations at WDU, including:

§ 6Mtpa crushing and haulage capacity via the existing shaft. The crusher is located at a depth of approximately 1,000m and would be accessible from WDU by development of a ~1.5km lateral haulage drive;

§ Water pumping infrastructure with installed capacity of 132L/s, with current mining activities in the MDU utilising on average 50L/s;

§ Ventilation infrastructure designed for ~5Mtpa SLC, currently operating as a ~1.2Mtpa stoping operations;

§ Electricity generation from the Telfer power plant and transmission via the MDU; and

§ Paste plant.

Figure 4: MDU shaft headframe (left), underground conveyor system (right)

|

|

Figure 5: MDU water pumping station (left) and paste plant (right foreground)

|

|

Development and study work

The current drilling program is on track to inform a maiden Mineral Resource estimate targeted in the March 2026 quarter and provide input into metallurgical and geotechnical test work.

The second parallel development drive from MDU to WDU has now been developed to a length of approximately 1,100 metres, providing a primary ventilation loop and is approximately 60% of the way to the existing diamond drill location, which sits 200-300m from the WDU mineralisation. This drive will facilitate greater rates of exploration drilling and the option to accelerate early works development.

A pre-feasibility study for WDU is underway, with metallurgical, hydrogeology, and geotechnical testwork program scheduled in H2 FY26. The study will assess the utilisation of the existing MDU infrastructure, along with key infrastructure components such as upgrading the existing paste plant (Figure 5 above), and the tailings supply options for paste backfill. It will also consider processing optimisation with future Havieron ore.

Contact

For further information, please contact:

Greatland Resources Limited

Shaun Day, Managing Director | Rowan Krasnoff, Chief Development Officer

Nominated Advisor

SPARK Advisory Partners

Andrew Emmott / James Keeshan / Neil Baldwin | +44 203 368 3550

Corporate Brokers

Canaccord Genuity | James Asensio / George Grainger | +44 207 523 8000

RBC Capital Markets | James Agnew / Jamil Miah | Scott Redwood | +44 207 029 0528

Media Relations

Australia - Fivemark Partners | Michael Vaughan | +61 422 602 720

About Greatland

Greatland is a gold and copper mining company listed on the Australian Securities Exchange and London Stock Exchange's AIM Market (ASX:GGP and AIM:GGP) and operates its business from Western Australia.

The Greatland portfolio includes the 100% owned Telfer mine, the adjacent 100% owned brownfield world-class Havieron gold-copper development project, and a significant exploration portfolio within the surrounding region. The combination of Telfer and Havieron provides for a substantial and long life gold-copper operation in the Paterson Province in the East Pilbara region of Western Australia.

Forward Looking Statements

This document includes forward looking statements and forward looking information within the meaning of securities laws of applicable jurisdictions. Forward looking statements can generally be identified by the use of words such as "may", "will", "expect", "intend", "plan", "estimate", "anticipate", "believe", "continue", "objectives", "targets", "outlook" and "guidance", or other similar words and may include, without limitation, statements regarding estimated reserves and resources, certain plans, strategies, aspirations and objectives of management, anticipated production, study or construction dates, expected costs, cash flow or production outputs and anticipated productive lives of projects and mines.

These forward looking statements involve known and unknown risks, uncertainties and other factors that may cause actual results, performance and achievements or industry results to differ materially from any future results, performance or achievements, or industry results, expressed or implied by these forward-looking statements. Relevant factors may include, but are not limited to, changes in commodity prices, foreign exchange fluctuations and general economic conditions, increased costs and demand for production inputs, the speculative nature of exploration and project development, including the risks of obtaining necessary licences and permits and diminishing quantities or grades of reserves, political and social risks, changes to the regulatory framework within which Greatland operates or may in the future operate, environmental conditions including extreme weather conditions, recruitment and retention of personnel, industrial relations issues and litigation.

Forward looking statements are based on assumptions as to the financial, market, regulatory and other relevant environments that will exist and affect Greatland's business and operations in the future. Greatland does not give any assurance that the assumptions will prove to be correct. There may be other factors that could cause actual results or events not to be as anticipated, and many events are beyond the reasonable control of Greatland. Forward looking statements in this document speak only at the date of issue. Greatland does not undertake any obligation to update or revise any of the forward looking statements or to advise of any change in assumptions on which any such statement is based.

Competent Persons Statement

Information in the report pertaining to exploration results has been reviewed and approved by Mr Michael Thomson, a Member of the Australian Institute of Geoscientists (AIG), who has more than 20 years relevant industry experience. Mr Thomson, an employee of the Company, has sufficient experience relevant to the style of mineralisation, type of deposit under consideration, and to the activity which he is undertaking to qualify as a Competent Person as defined by the 2012 Edition of the Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves (the JORC Code) and under the AIM Rules - Note for Mining and Oil & Gas Companies, which outline standards of disclosure for mineral projects. Mr Thomson consents to the inclusion in this announcement of the matters based on this information in the form and context in which it appears.

Drillhole Data and Au- Cu Significant Intersections

Reporting Criteria: Intercepts reported are downhole drill width (not true width) Au >0.50ppm (0.5g/t Au) and minimum 1m downhole width with maximum consecutive internal dilution of 5m. Average grades are based on length-weighting of samples grade, and only those intercepts with a gram metres (Au_ppm x length) above 10 gram metres have been reported. Gold and copper grades are reported to two significant figures, the downhole lengths are rounded to 0.1m which may cause some apparent discrepancies in interval widths. Underground samples are from core drilling which is NQ2 in diameter while open pit samples are from reverse circulation (RC) drilling.

Table 1: WDU New significant intercepts & drilling data (Mine Grid)

| WUC4550081 | 58782 | 13067 | 4421 | 13.52 | 272.7 | 411.5 | 155 | 159.75 | 4.8 | 1.68 | 0.13 | 8 |

| 309 | 333 | 24.0 | 1.18 | 0.09 | 28 | |||||||

| 341 | 369 | 28.0 | 1.85 | 0.35 | 52 | |||||||

| WUC4550082 | 58782 | 13065 | 4422 | 9.17 | 267.8 | 397.7 | 233.5 | 243 | 9.5 | 1.37 | 0.05 | 13 |

| WUC4550083 | 58782 | 13066 | 4421 | 16.65 | 268.1 | 466.3 | 154.65 | 161.31 | 6.7 | 1.88 | 0.39 | 12 |

| 335 | 391.64 | 56.6 | 2.28 | 1.23 | 129 | |||||||

| 391.64 | 397.15 | 5.5 | 3.66 | 0.28 | 20 | |||||||

| WUC4550085 | 58782 | 13066 | 4421 | 16.65 | 268.1 | 466.3 | 334 | 400.5 | 66.5 | 1.17 | 0.16 | 78 |

| 416.03 | 423.18 | 7.2 | 2.32 | 0.13 | 17 | |||||||

| WUC4550092 | 58783 | 13053 | 4421 | 21.12 | 263.7 | 534.7 | 167.77 | 171.62 | 3.8 | 4.13 | 0.38 | 16 |

| 358 | 440.2 | 82.2 | 1.90 | 0.31 | 156 | |||||||

| 440.24 | 447.1 | 6.9 | 2.28 | 0.26 | 16 | |||||||

| WUC4550098 | 58783 | 13044 | 4422 | 8.32 | 251.1 | 450 | 322.5 | 335.73 | 13.2 | 0.91 | 0.03 | 12 |

| WUC4550099 | 58782 | 13044 | 4421 | 12 | 243 | 472.5 | 281 | 311 | 30.0 | 5.58 | 0.25 | 167 |

| 234 | 269 | 35.0 | 2.91 | 0.19 | 102 | |||||||

| 327.7 | 329 | 1.3 | 11.62 | 0.09 | 15 | |||||||

| 396 | 453 | 57.0 | 3.02 | 0.19 | 172 | |||||||

| 396* | 418.5 | 22.5 | 1.43 | 0.01 | 32 | |||||||

| 418.5* | 453 | 34.5 | 4.06 | 0.31 | 140 | |||||||

| 359 | 361 | 2.0 | 7.24 | 0.00 | 14 | |||||||

| WUC4550111 | 58783 | 13030 | 4422 | 329 | 14.0 | 233 | 302.3 | 329 | 26.6 | 2.69 | 0.30 | 72 |

| WUC4550102 | 58784 | 13036 | 4422.178 | 7.9 | 249.8 | 508.5 | 209.4 | 222 | 12.6 | 1.39 | 0.13 | 17 |

(*) Note these intercepts area subset of a larger interval the precede them.

Table 2: Historical WDU significant intercepts & drilling data (Mine Grid)

| UG Ph1 | WUC4550007 | 58771 | 13138 | 4421 | 303 | 6 | 380 | 107 | 109.2 | 2.2 | 2 | 0.43 | 4 |

| 114.7 | 121 | 6.3 | 3.14 | 0.11 | 20 | ||||||||

| 126 | 128.5 | 2.5 | 4.24 | 0.04 | 11 | ||||||||

| 259 | 318 | 59 | 2.83 | 0.71 | 167 | ||||||||

| 360.3 | 362.3 | 2.1 | 2.09 | 0.83 | 4 | ||||||||

| UG Ph1 | WUC4550008 | 58771 | 13138 | 4421 | 295.3 | 13 | 410 | 131 | 136.7 | 5.7 | 1.01 | 0.06 | 6 |

| 266 | 276 | 10 | 0.64 | 0.05 | 6 | ||||||||

| 311 | 319 | 8 | 0.6 | 0.07 | 5 | ||||||||

| 328 | 334.4 | 6.4 | 3.87 | 0.05 | 25 | ||||||||

| UG Ph1 | WUC4550009A | 58771 | 13137 | 4421 | 289.2 | -2 | 318 | 132.1 | 144.7 | 12.6 | 1.6 | 0.07 | 20 |

| 151 | 188 | 37 | 1.27 | 0.05 | 47 | ||||||||

| 268.6 | 291.3 | 22.7 | 2.71 | 1.43 | 62 | ||||||||

| UG Ph1 | WUC4550010 | 58772 | 13138 | 4421 | 312 | 12 | 400 | 102.6 | 109.5 | 6.8 | 6.88 | 0.39 | 47 |

| UG Ph1 | WUC4550012 | 58772 | 13138 | 4421 | 321.5 | 1.5 | 430 | 126.7 | 130 | 3.3 | 1.9 | 0.6 | 6 |

| 278 | 287.3 | 9.3 | 5.44 | 1.41 | 51 | ||||||||

| 341 | 353.3 | 12.3 | 3.17 | 0.83 | 39 | ||||||||

| Incl | 323.5 | 336 | 12.5 | 3.71 | 1.03 | 46 | |||||||

| 430 | 370 | 375 | 5 | 6.68 | 0.03 | 33 | |||||||

| 384.9 | 389 | 4.1 | 0.56 | 0.91 | 2 | ||||||||

| UG Ph1 | WUC4550013 | 58771 | 13136 | 4420 | 295.2 | 6 | 380 | 112 | 116.6 | 4.6 | 1.49 | 0.02 | 7 |

| 286.6 | 301.8 | 15.2 | 3.31 | 3 | 50 | ||||||||

| 323 | 324 | 1 | 7.87 | 0.65 | 8 | ||||||||

| 354.5 | 377.4 | 22.9 | 0.65 | 0.11 | 15 | ||||||||

| UG Ph1 | WUC4550016 | 58770 | 13105 | 4420 | 341.2 | 4 | 354 | 152.3 | 161 | 8.7 | 0.75 | 0.05 | 7 |

| 179 | 180 | 1 | 5.37 | 0 | 5 | ||||||||

| 223.2 | 237 | 13.9 | 2.83 | 0.28 | 39 | ||||||||

| 300.2 | 321 | 20.9 | 4.27 | 2.77 | 89 | ||||||||

| 344.4 | 344.8 | 0.4 | 17.6 | 5.91 | 7 | ||||||||

| UG Ph1 | WUC4550017 | 58770 | 13105 | 4421 | 274.7 | -1 | 155 | drillhole failed to reach target | |||||

| UG Ph1 | WUC4550018 | 58770 | 13105 | 4420 | 278.5 | 21 | 423 | 175 | 183 | 8 | 1.27 | 0.1 | 10 |

| 198 | 206.5 | 8.5 | 0.63 | 0.6 | 5 | ||||||||

| 294 | 325 | 31 | 1.18 | 0.38 | 37 | ||||||||

| 376 | 382.5 | 6.5 | 1.05 | 0.25 | 7 | ||||||||

| UG Ph1 | WUC4550019 | 58770 | 13104 | 4420 | 281 | 11 | 390 | 269 | 287.1 | 18.1 | 1.53 | 0.08 | 28 |

| 294 | 336 | 42 | 1.97 | 0.49 | 83 | ||||||||

| UG Ph1 | WUC4550020 | 58770 | 13105 | 4420 | 274.6 | 14 | 428 | 272.9 | 282.9 | 10 | 0.64 | 0.09 | 6 |

| 305.8 | 315 | 9.2 | 2.01 | 0.15 | 18 | ||||||||

| 330.6 | 349 | 18.4 | 3.93 | 0.92 | 72 | ||||||||

| UG Ph1 | WUC4550021 | 58771 | 13114 | 4420 | 274.6 | 14 | 429 | 113.7 | 121 | 7.3 | 0.55 | 0.47 | 4 |

| 308 | 318.5 | 10.5 | 0.51 | 0.51 | 5 | ||||||||

| UG Ph1 | WUC4550022 | 58771 | 13113 | 4420 | 289.5 | 6.5 | 400 | 121.7 | 128.2 | 6.6 | 1.64 | 1.14 | 11 |

| 159.9 | 161.3 | 1.4 | 7.16 | 0.07 | 10 | ||||||||

| 228.7 | 234 | 5.3 | 0.87 | 0.09 | 5 | ||||||||

| 290.4 | 304.7 | 14.3 | 9.06 | 8.57 | 130 | ||||||||

| 347.5 | 352.6 | 5.1 | 1.39 | 1.18 | 7 | ||||||||

| 366 | 397.7 | 31.7 | 1.34 | 0.35 | 42 | ||||||||

| UG Ph1 | WUC4550023 | 58784 | 13038 | 4422 | 248.5 | 11.5 | 516 | 53 | 54 | 1 | 11.4 | 0.13 | 11 |

| 205 | 212.5 | 7.4 | 1.23 | 0.31 | 9 | ||||||||

| 317.3 | 329.7 | 12.5 | 5.08 | 0.52 | 64 | ||||||||

| 365.9 | 402 | 36.1 | 2.14 | 0.21 | 77 | ||||||||

| 408 | 416 | 8 | 3.6 | 0.5 | 29 | ||||||||

| UG Ph1 | WUC4550030 | 58783 | 13063 | 4421 | 270.6 | 14 | 429 | 147 | 164 | 17 | 0.54 | 0.13 | 9 |

| 182.8 | 188.7 | 5.9 | 1.04 | 0.61 | 6 | ||||||||

| 319 | 325 | 6 | 1.02 | 0.01 | 6 | ||||||||

| 341 | 364.3 | 23.3 | 1.64 | 0.54 | 38 | ||||||||

| 370 | 381.8 | 11.8 | 2.09 | 0.15 | 25 | ||||||||

| UG Ph1 | WUC4550032 | 58783 | 13062 | 4422 | 267.4 | 9.8 | 425 | 117 | 118 | 1 | 27.3 | 0.02 | 27 |

| 157.5 | 163 | 5.5 | 1.92 | 0.06 | 11 | ||||||||

| 171.1 | 181 | 9.9 | 0.55 | 0.07 | 5 | ||||||||

| 282.3 | 294 | 11.7 | 0.86 | 0.01 | 10 | ||||||||

| 305.5 | 326.4 | 20.9 | 4.07 | 0.49 | 85 | ||||||||

| 336.9 | 360 | 23.1 | 1.13 | 0.49 | 26 | ||||||||

| 399 | 408 | 9 | 2.91 | 0.24 | 26 | ||||||||

| 421.1 | 423 | 1.9 | 5.24 | 1.12 | 10 | ||||||||

| UG Ph1 | WUC4550035 | 58783 | 13062 | 4422 | 261 | 11.3 | 460 | 163.8 | 169.4 | 5.7 | 1.17 | 0.21 | 7 |

| 213.5 | 221 | 7.5 | 0.73 | 0.04 | 5 | ||||||||

| 246 | 246.5 | 0.5 | 28.8 | 0.02 | 14 | ||||||||

| 266 | 286 | 20 | 2.47 | 0.03 | 49 | ||||||||

| 326.7 | 349 | 22.3 | 2.41 | 1.66 | 54 | ||||||||

| 354.6 | 355.2 | 0.6 | 5.87 | 2.48 | 4 | ||||||||

| 361 | 367 | 6 | 3.37 | 0.26 | 20 | ||||||||

| 374 | 386.1 | 12.1 | 0.92 | 0.64 | 11 | ||||||||

| 407 | 407.3 | 0.3 | 32.2 | 0.85 | 10 | ||||||||

| 426.6 | 436 | 9.4 | 0.51 | 0.07 | 5 | ||||||||

| UG Ph1 | WUC4550040 | 58771 | 13104 | 4420 | 276 | 3.5 | 376 | 140.9 | 142.9 | 2 | 10.01 | 0.07 | 20 |

| 203 | 230 | 27 | 0.7 | 0.22 | 19 | ||||||||

| 268 | 279 | 11 | 1.72 | 0.86 | 19 | ||||||||

| 284.7 | 316.3 | 31.6 | 3.09 | 0.6 | 98 | ||||||||

| UG Ph1 | WUC4550041 | 58771 | 13138 | 4421 | 299.4 | 2.5 | 370 | 114 | 122.4 | 8.4 | 1.23 | 0.07 | 10 |

| 190 | 191 | 1 | 6.82 | 0.01 | 7 | ||||||||

| 291 | 305 | 14 | 2.55 | 1.13 | 36 | ||||||||

| 348.7 | 364 | 15.3 | 0.71 | 0.37 | 11 | ||||||||

| Historic | WRC34101 | 59013 | 13417 | 5519 | 229 | 77 | 1543 | 1497 | 1504 | 7 | 1.27 | 0.04 | 9 |

| Historic | WRC33404W1 | 58528 | 13351 | 5372 | 183.5 | 70.5 | 1243 | 903.8 | 915.7 | 11.9 | 1.5 | 0.01 | 18 |

| 922 | 923.2 | 1.1 | 5.7 | 0.08 | 6 | ||||||||

| 931.8 | 946 | 14.2 | 0.93 | 0.13 | 13 | ||||||||

| 957.1 | 958.1 | 1 | 7.41 | 3.45 | 7 | ||||||||

| 972.9 | 983 | 10.1 | 3.91 | 0.02 | 39 | ||||||||

| 1076.7 | 1091 | 14.3 | 0.45 | 0.06 | 6 | ||||||||

| 1152 | 1157.7 | 5.8 | 0.75 | 0.11 | 4 | ||||||||

| Historic | WRC32801A | 57649 | 13289 | 5512 | 94 | 80.5 | 1870 | 1156.7 | 1164.5 | 7.8 | 0.56 | 0.16 | 4 |

| 1681.7 | 1689.1 | 7.4 | 1.38 | 1.6 | 10 | ||||||||

| 1695.9 | 1702 | 6.2 | 0.58 | 0.5 | 4 | ||||||||

| 1713.7 | 1721 | 7.3 | 0.71 | 0.78 | 5 | ||||||||

| 1721.1 | 1722.4 | 1.3 | 8.96 | 4.39 | 12 | ||||||||

| 1730.7 | 1734 | 3.3 | 1.96 | 0.1 | 6 | ||||||||

| 1768 | 1787 | 19 | 0.7 | 0.61 | 13 | ||||||||

| 1796.5 | 1810.5 | 14 | 1.17 | 0.28 | 16 | ||||||||

| 1844.9 | 1867 | 22.1 | 1.06 | 0.08 | 23 | ||||||||

| Historic | WRC30582W1 | 58761 | 13037 | 5439 | 262 | 87 | 1679 | 883 | 884 | 1 | 13.6 | 1.46 | 14 |

| 1611 | 1612 | 1 | 6.36 | 0.51 | 6 | ||||||||

| 1390 | 1396.6 | 6.6 | 0.9 | 0.09 | 6 | ||||||||

| 1252 | 1256 | 4 | 1.32 | 0.07 | 5 | ||||||||

| 1362.5 | 1377 | 14.5 | 0.76 | 0.09 | 11 | ||||||||

| 1546 | 1559 | 13 | 0.77 | 0.08 | 10 | ||||||||

| 1420 | 1424 | 4 | 1.35 | 0.11 | 5 | ||||||||

| Historic | WRC28605B | 59234 | 12825 | 5521 | 262 | 72.1 | 1702 | 1357.5 | 1370 | 12.5 | 1.87 | 0.31 | 23 |

| 1389 | 1417 | 28 | 0.29 | 0.09 | 8 | ||||||||

| 1541 | 1551.3 | 10.3 | 0.37 | 0.18 | 4 | ||||||||

| 1565 | 1577 | 12 | 1.18 | 0.59 | 14 | ||||||||

| 1601.5 | 1609 | 7.5 | 1.25 | 0.1 | 9 | ||||||||

| Historic | WRC28048W4 | 59265 | 12799 | 5521 | 216.25 | 71.88 | 1776 | 1414 | 1415 | 1 | 15.67 | 0.03 | 16 |

| 1499.8 | 1511.8 | 12 | 0.39 | 0.05 | 5 | ||||||||

| 1636 | 1641.6 | 5.6 | 2.86 | 0.03 | 16 | ||||||||

| 1657 | 1669.5 | 12.5 | 1.6 | 0.22 | 20 | ||||||||

| 1753.7 | 1756 | 2.3 | 3.17 | 0.08 | 7 | ||||||||

| Historic | WRC28048W2 | 59265 | 12799 | 5521 | 216 | 70 | 1801 | 1286 | 1286.5 | 0.5 | 11.64 | 0.06 | 6 |

| 1592 | 1602 | 10 | 1.37 | 0.32 | 14 | ||||||||

| 1614.6 | 1621.3 | 6.7 | 1.45 | 0.26 | 10 | ||||||||

| 1645.9 | 1653 | 7.1 | 2.97 | 0.25 | 21 | ||||||||

| Historic | WRC28048W1 | 59265 | 12799 | 5521 | 216 | 70 | 1670 | 1626 | 1648 | 22 | 0.38 | 0.05 | 8 |

| 859 | 860 | 1 | 5.62 | 0.02 | 6 | ||||||||

| 1130.6 | 1136.8 | 6.2 | 1.48 | 0.03 | 9 | ||||||||

| 1321 | 1329 | 8 | 16.03 | 0.23 | 128 | ||||||||

| 1335 | 1336 | 1 | 5.7 | 0.05 | 6 | ||||||||

| 1353.6 | 1356 | 2.4 | 1.98 | 0.09 | 5 | ||||||||

| 1390.7 | 1400 | 9.3 | 0.54 | 0.28 | 5 | ||||||||

| 1528 | 1531 | 3 | 1.73 | 0.08 | 5 | ||||||||

| Historic | WRC31558 | 58150 | 13150 | 5517 | 90 | 85 | 1850 | 1195.2 | 1228 | 32.8 | 2.05 | 0.48 | 67 |

| 1274 | 1287.9 | 13.9 | 0.9 | 0.57 | 13 | ||||||||

| 1299.7 | 1307 | 7.3 | 0.54 | 0.91 | 4 | ||||||||

| 1404.8 | 1407.8 | 3 | 1.64 | 0.42 | 5 | ||||||||

| 1519.2 | 1523.3 | 4 | 4.89 | 0.74 | 20 | ||||||||

| 1542.4 | 1549.5 | 7.1 | 0.58 | 0.16 | 4 | ||||||||

| 1595.8 | 1596.5 | 0.8 | 7.2 | 0.73 | 6 | ||||||||

| 1669.6 | 1679 | 9.4 | 1.33 | 0.25 | 13 | ||||||||

| Historic | WRC33901 | 58118 | 13394 | 5517 | 89 | 75.5 | 1330 | 1050.3 | 1060.1 | 9.8 | 1.57 | 0.18 | 15 |

| 1050.3 | 1060.1 | 9.8 | 1.57 | 0.18 | 15 | ||||||||

| 1090.3 | 1111 | 20.8 | 0.65 | 0.13 | 14 | ||||||||

| 1090.3 | 1111 | 20.8 | 0.65 | 0.13 | 14 | ||||||||

| 1119 | 1129.1 | 10.1 | 0.73 | 0.27 | 7 | ||||||||

| 1119 | 1129.1 | 10.1 | 0.73 | 0.27 | 7 | ||||||||

| 1216 | 1235.3 | 19.3 | 2.03 | 0.06 | 39 | ||||||||

| 1216 | 1235.3 | 19.3 | 2.03 | 0.06 | 39 | ||||||||

| Historic | WRC31561 | 58831 | 13150 | 5485 | 270 | -70 | 1713 | 1170.4 | 1175.3 | 4.9 | 1.56 | 1.36 | 8 |

| 1190 | 1200 | 10 | 0.9 | 0.28 | 9 | ||||||||

| 1266.1 | 1269 | 2.9 | 1.46 | 0.28 | 4 | ||||||||

| 1290.2 | 1290.7 | 0.6 | 58.5 | 0.08 | 35 | ||||||||

| Historic | WRC34081 | 58068 | 13422 | 5515 | 90 | 85 | 1519 | 891 | 908 | 17 | 1.08 | 0.05 | 18 |

| 1182 | 1189 | 7 | 0.97 | 0.04 | 7 | ||||||||

| 1216 | 1219.1 | 3.1 | 0.96 | 1.67 | 3 | ||||||||

| 1225.7 | 1246.1 | 20.4 | 5.17 | 0.39 | 105 | ||||||||

| 1482 | 1489 | 7 | 1.57 | 0.04 | 11 | ||||||||

| Historic | W32736W1 | 57952 | 13254 | 5524 | 90 | 85 | 1411 | 762 | 764 | 2 | 4.29 | 0.13 | 9 |

| 771 | 781 | 10 | 0.94 | 0.14 | 9 | ||||||||

| 941.9 | 949 | 7.1 | 0.88 | 0.04 | 6 | ||||||||

| 1231 | 1238 | 7 | 1.82 | 0.22 | 13 | ||||||||

| 1256 | 1283.1 | 27.1 | 1.31 | 0.76 | 36 | ||||||||

| 1291.4 | 1293 | 1.6 | 1.56 | 1.81 | 2 | ||||||||

| Historic | W27563W1 | 57964 | 12751 | 5528 | 80 | -85.3 | 1479 | 1091 | 1109.1 | 18.1 | 0.78 | 0.01 | 14 |

| 1285 | 1301.2 | 16.2 | 1.52 | 0.16 | 25 | ||||||||

| 1318 | 1346 | 28 | 0.96 | 0.16 | 27 | ||||||||

| Historic | WRC30070 | 57965 | 13044 | 5512 | 94 | -85 | 1509 | 694.3 | 699.6 | 5.3 | 13.48 | 0.14 | 71 |

| 718.9 | 736 | 17 | 2.05 | 0.31 | 35 | ||||||||

| 744.7 | 749.2 | 4.6 | 0.96 | 0.66 | 4 | ||||||||

| 847.5 | 851 | 3.5 | 3.01 | 0.26 | 11 | ||||||||

| 980.9 | 992 | 11.1 | 1.02 | 0.04 | 11 | ||||||||

| 1024.3 | 1033.4 | 9 | 3.65 | 0.03 | 33 | ||||||||

| 1041.9 | 1073 | 31.1 | 0.85 | 0.03 | 26 | ||||||||

| 1093 | 1104 | 11 | 0.5 | 0.03 | 6 | ||||||||

| 1291 | 1326 | 35 | 3.3 | 0.24 | 116 | ||||||||

| 1334 | 1342 | 8 | 0.54 | 0.1 | 4 | ||||||||

| 1375 | 1377.9 | 2.9 | 0.76 | 1.06 | 2 | ||||||||

| 1403 | 1413.6 | 10.6 | 1.93 | 0.95 | 20 | ||||||||

| 1441.8 | 1454 | 12.2 | 1.47 | 0.13 | 18 | ||||||||

| 1481.3 | 1487 | 5.8 | 2.14 | 0.15 | 12 | ||||||||

| Historic | W30070W1 | 57965 | 13044 | 5512 | 94 | -85 | 1520 | 844 | 854.4 | 10.4 | 0.86 | 0.06 | 9 |

| 877 | 879 | 2 | 3.49 | 0.01 | 7 | ||||||||

| 889 | 892 | 3 | 1.74 | 0.01 | 5 | ||||||||

| 983.1 | 993 | 9.9 | 0.78 | 0.06 | 8 | ||||||||

| 1024 | 1055.4 | 31.4 | 0.85 | 0.02 | 27 | ||||||||

| 1109 | 1114.9 | 5.9 | 1.16 | 0.05 | 7 | ||||||||

| 1190.4 | 1191.4 | 0.9 | 12.52 | 0.01 | 11 | ||||||||

| 1261 | 1274 | 13 | 2.06 | 0.67 | 27 | ||||||||

| 1284.3 | 1305 | 20.7 | 1.65 | 0.49 | 34 | ||||||||

| Historic | W31567W1 | 57944 | 13158 | 5524 | 90 | -85 | 1639 | 975 | 983 | 8 | 0.97 | 0.01 | 8 |

| 988.6 | 998 | 9.4 | 0.6 | 0 | 6 | ||||||||

| 1050.7 | 1082 | 31.3 | 4.43 | 0.03 | 139 | ||||||||

| 1214 | 1221 | 7 | 0.94 | 0.17 | 7 | ||||||||

| 1306.1 | 1363 | 57.1 | 1.14 | 0.3 | 65 | ||||||||

| 1353 | 1362.8 | 9.8 | 0.53 | 0.21 | 5 | ||||||||

| 1390.8 | 1452.4 | 61.6 | 1.45 | 0.46 | 89 | ||||||||

| 1472.2 | 1475 | 2.8 | 0.69 | 1.96 | 2 | ||||||||

| 1533.9 | 1537 | 3.1 | 9.58 | 1.02 | 30 | ||||||||

| 1553.8 | 1558 | 4.2 | 0.88 | 0.81 | 4 | ||||||||

| 1575.6 | 1590 | 14.4 | 1.73 | 0.18 | 25 | ||||||||

| Historic | WRC29044 | 57964 | 12904 | 5530 | 90 | -85 | 1550 | 1100 | 1101 | 1 | 5.59 | 0 | 6 |

| 1100 | 1110 | 10 | 1.06 | 0.01 | 11 | ||||||||

| 1119 | 1142 | 22.6 | 0.93 | 0 | 21 | ||||||||

| 1177 | 1230 | 53 | 1.32 | 0.06 | 70 | ||||||||

| 1200 | 1201 | 1 | 5.98 | 0.04 | 6 | ||||||||

| 1212 | 1214 | 2 | 15.08 | 0.16 | 30 | ||||||||

| 1226.9 | 1228 | 1.2 | 5.42 | 0.14 | 7 | ||||||||

| 1292 | 1297 | 5 | 1.59 | 0.04 | 8 | ||||||||

| 1319.7 | 1321 | 1.4 | 21.56 | 0.1 | 30 | ||||||||

| 1319.7 | 1332 | 12.4 | 11.08 | 0.32 | 137 | ||||||||

| 1322 | 1324 | 2 | 16.18 | 0.17 | 32 | ||||||||

| 1325 | 1326.7 | 1.7 | 26.89 | 0.71 | 46 | ||||||||

| 1327 | 1328 | 1 | 7.73 | 0.35 | 8 | ||||||||

| 1331 | 1332 | 1 | 14.51 | 0.14 | 15 |

JORC 2012 Table 1 : Section 1 - Sampling Techniques and Data

| Criteria | Commentary |

| Sampling techniques | Resource definition drilling at Telfer involves a combination of reverse circulation (RC) and diamond drilling throughout the mining period. For diamond drilling, samples are taken according to lithological boundaries, with geologists defining sample intervals and selecting the assay methodology. Historically, high-grade reef samples were sent for screen fire assay, while other samples underwent fire assay for gold and additional elements. Core sizes for resource drilling usually range from NQ to PQ, while smaller sizes (NQ or LTK60) are used for grade control. Diamond drilling typically samples lithological units with lengths between 0.2 to 1.2 meters, with 1-meter intervals being most common and they are barcoded and submitted for laboratory analysis. Historically, RC drilling typically produces 1-meter samples, from which a 2-5 kg sub-sample is taken using a riffle splitter, then pulverised for gold assay. Earlier RC drilling involved samples from 0.5-meter to 2-meter intervals, with the small intervals were used to target reefs. Recent RC drilling for resource definition uses 1-meter intervals and split using cone splitter from which a 2-5 kg sub-sample is taken with bulk reject material stored temporarily. While grade control uses 2-meter intervals and split using cone splitter. All RC drilling has field duplicates conducted at a 1:20 ratio. Rock chip samples, collected manually from exposed development faces, are typically 2-3 kg, collected perpendicular to bedding, and include all relevant domains (reef, hanging wall, footwall). These samples are stored in pre-numbered bags for analysis. |

| Drilling techniques | Drilling at the Telfer has evolved over time, following industry-standard protocols. Before 1998, drilling targeted mainly previously mined areas, while from 1998 to 2002, diamond drilling formed the primary data source for current Mineral Resource estimates, supplemented by RC drilling. Currently, RC drilling is the primary data source for the open pit resources and diamond drilling for underground resources. Currently, NQ2 is the dominant drill size for diamond drilling and RC Drilling is drilled with a pre-collar of 143mm then reduced to 134mm diameter. Additional core sizes, including NQ, HQ, HQ3, LTK60, and limited PQ and BQ, have also been used at Telfer. LTK60 and BQ have mainly been used for grade control. The Reflex orientation tool is used by drillers, with all core being oriented using Ezy-Mark to mark the bottom of the hole. The core is then re-constructed in V-Rail, where the orientation line is drawn along the core |

| Drill sample recovery | Core recovery data from diamond drilling is systematically recorded by comparing drillers' depth blocks with database records and is stored in the geological database. If excessive core loss occurs, a wedge hole is often drilled to recover the lost interval. A review in 2019 confirmed no significant relationship between sample recovery and grade for either core or RC samples, with high core recovery minimising potential loss effects. Following the review, weighing each RC sample at the rig was implemented to ensure consistent sample support in resource estimation. |

| Logging | Geological logging is conducted for all diamond and reverse circulation (RC) drill holes, capturing lithology, alteration, mineralisation, veining, and structure (for diamond core). Diamond drill holes are also quantitatively logged for veining, vein percentage, and structure. All drill core is photographed before sampling, using either slide film or digital cameras. Logged data is validated before merging into the database, which contains over 1,000 km of logged geology, covering approximately 80% of total drilling. Rock Quality Designation (RQD) is routinely recorded, with around 900 diamond holes geotechnically assessed. The level of logging detail is appropriate for resource estimation and related studies. |

| Sub-sampling techniques and sample preparation | Sampling and quality control procedures are designed for the material being tested. Geologists define sample intervals to avoid crossing key lithological contacts and select appropriate assay methods. Diamond core is typically sampled as half-core, while RC samples are collected dry, with conditions recorded. Since 2015, cone splitters have replaced riffle splitters for RC sampling, with field duplicates taken at a 1:20 ratio. Core samples are processed through drying, crushing, and pulverising, with historical standards requiring 90% passing 75 µm. Older RC drilling used 0.5-2 m intervals, while recent resource definition drilling follows 1 m intervals (2 m for grade control), with a 5 kg primary split collected. Samples are prepared at the Telfer lab, where they are crushed, sub-split, and pulverised to 95% passing 106 µm. Gold is analysed via 30 g fire assay, while base metals, sulphur, and arsenic are tested by ICP. Cyanide-soluble copper is determined by bottle roll leach with AAS analysis. To ensure accuracy, 1 in 20 samples undergo external lab verification. |

| Quality of assay data and laboratory tests | Assay and quality control protocols at the Telfer deposit have evolved to align with industry standards. Before 1998, quality control procedures followed industry norms of the time, with no major concerns identified. From 1998 onwards, protocols were enhanced, particularly during prefeasibility and feasibility studies conducted between 1998 and 2002. Samples are primarily prepared at the Telfer laboratory and then sent to external commercial labs for analysis. Currently, all resource definition samples have been assayed through a combination of the Telfer Laboratory and the Bureau Veritas (BV) Commercial Lab in Perth and all grade control samples have been sent through Telfer Laboratory. Gold is analysed using fire assay, while multi-element analyses-including silver, arsenic, bismuth, copper, iron, nickel, lead, sulphur, and zinc-are conducted using ICP techniques. Cyanide-soluble copper is assessed via bottle roll leach with AAS analysis. Since 1998, comprehensive quality control measures have been in place, including the use of Certified Reference Materials (CRMs), blanks, duplicate assays, blind pulp re-submissions and checks at independent laboratories. Matrix-matched CRMs were introduced in 1999, and transition to multi client CRMs in 2018. Since 2000, Telfer's laboratory was managed by commercial organisations until Telfer re-opening in 2002 has been managed by Newcrest and now, Greatland. Regular reviews of Quality Assurance and Quality Control (QAQC) procedures, including sample resubmissions and bias assessments, help ensure data accuracy and reliability. Monthly reports document any anomalies, with corrective actions taken as needed. Comparison studies, including analyses of duplicate pulp samples sent to external laboratories, confirm data precision, with a 90% repeatability rate. The QAQC protocols and assay techniques used are considered reliable for Mineral Resource estimation. During the 2002 feasibility study, 13,570 pulp duplicate samples were dispatched from the Telfer preparation laboratory for analysis at a check laboratory. Insignificant bias was identified between the original and check laboratories for gold (-0.8%) and copper (0.5%). |

| Verification of sampling and assaying | Drill hole data is securely stored in an acQuire database, with stringent controls to ensure data integrity and prevent errors or duplication. Data collection, including collar coordinates, drill hole designation, logging, and assaying, follows strict protocols to maintain accuracy. Validation involves multiple stages, with input from geologists, surveyors, assay laboratories, and down-hole surveyors where applicable. Data entry has evolved from manual methods to direct digital input, incorporating automated validation checks. Internal and external reviews further enhance data quality before resource estimation. Resource data is managed daily by site geologists, with additional verification by a centralised resource team. Sampling details are recorded digitally, utilising barcode and tracking systems to monitor sample integrity throughout the process. Recent drilling programs employ numbered bags for tracking consistency. Regular audits of both internal and commercial laboratories ensure compliance with quality standards. No assay data adjustments have been made in the Mineral Resource estimate. |

| Location of data points | Mining operations at Telfer Gold Mine adhere to periodic reporting requirements for the WA Department of Mines, Industry Regulation and Safety (DMIRS), using the MGA94/AHD coordinate system for official submissions. However, site operations utilise the Telfer Mine Grid (TMG) and Telfer Height Datum (THD), requiring coordinate transformations between the national and operational coordinate systems. This has been supplied by AAM Surveys in 1995 (AMG84 to Telfer Mine Grid) and AAMHATCH in February 2007 (Telfer Mine Grid to MGA Transformation). Both reports also addressed the height datum and in 2007 established the THD=AHD + 5193.7m. A local grid covers the whole of the Telfer mine area (Telfer Mine Grid 2002). It is oriented with grid north at 44o03'12' west of magnetic north. Topographic control is maintained through a combination of surface and aerial surveys, with routine updates for pits and underground voids. Drill hole collars are surveyed upon completion by mine surveyors. The natural surface topography, along with current pit surveys and underground voids (development, stopes and vertical openings) are used to deplete the resources and account for changes in mining areas at Telfer. Downhole survey methods have evolved over time, progressing from early single-shot cameras to modern electronic tools. Currently, drilling programs include multi-shot surveys at regular intervals, with post-completion surveys conducted at finer resolutions. Specific drilling campaigns may incorporate gyroscopic surveys where required. Routine in-pit drilling, particularly for pre-production and grade control, typically excludes downhole surveys, relying on collar surveys for accuracy. |

| Data spacing and distribution | The drill hole spacing is sufficient to demonstrate geological continuity appropriate for the Mineral Resource and the classifications applied under the 2012 JORC Code. The drill spacing applied to specific domains within the overall resource is variable and is considered suitable for the style of mineralisation and mineral resource estimation requirements. |

| Orientation of data in relation to geological structure | The Telfer mine site topography is dominated by two large scale asymmetric dome structures with steep west dipping axial planes. Main Dome is in the southeast portion of the mine and is exposed over a strike distance of 3 km north-south and 2 km east-west before plunging under transported cover. West Dome forms the topographical high in the northwest quadrant of the mine and has similar dimensions to Main Dome. Both fold structures have shallow to moderately dipping western limbs and moderate to steep dipping eastern limbs. Surface drilling is orientated to ensure optimal intersection angle for the reefs. Underground drilling orientation may be limited by available collar locations, but acceptable intersection angles are considered during the drill hole planning process. No orientation bias has been indicated in the drilling data. |

| Sample security | Sample security is maintained through a tracking system from drilling to database entry. While barcoding was previously used, it has been replaced with pre-numbered calico bags for resource development and underground drilling samples. All sample movements, including dispatch details, drill hole identification, sample ranges, and analytical requests, are recorded in a database. Any discrepancies identified upon receipt by the laboratory are validated to ensure data integrity. |

| Audits or reviews | In-house reviews of data, QAQC results, sampling protocols and compliance with corporate and site protocols are carried out at various frequencies by company employees not closely associated with the Telfer projects. Procedure audits and reviews are carried out by corporate employees during site visits. |

JORC 2012 Table 1: Section 2- Reporting of Exploration Results

| Criteria | Commentary |

| Mineral tenement and land tenure status | Mining and ore processing at Telfer operate under granted leases and licenses covering all key infrastructure, including open pits, underground resources, processing facilities, waste storage, and support services. The Telfer Main Dome Underground Mineral Resource is within mining leases M45/6 and M45/8, while the West Dome Mineral Resource, approximately 3km northwest of the Main Dome open pit, lies within leases M45/7 and M45/33. These leases are currently under renewal. An Indigenous Land Use Agreement (ILUA) has been in place since December 2015, covering all operational aspects of the site. Telfer operations also remain compliant with the Mining Rehabilitation Fund (MRF) levy. |

| Exploration done by other parties | The Telfer district was first geologically mapped by the Bureau of Mineral Resources in 1959, though no gold or copper mineralization was identified. In 1971, regional sampling by Day Dawn Minerals NL detected anomalous copper and gold at Main Dome. From 1972 to 1975, Newmont Pty Ltd conducted extensive exploration and drilling, defining an open pit reserve primarily in the Middle Vale Reef. In 1975, BHP Gold acquired a 30% stake in the project, and in 1990, Newmont and BHP Gold merged their Australian assets to form Newcrest Mining Limited. Newcrest managed exploration and resource drilling from 1990 until its acquisition by Newmont Corp on November 6, 2023. Newmont later divested Telfer, selling it to Greatland Gold on December 4, 2024, which now oversees exploration and drilling activities. |

| Geology | Telfer is located within the northwestern Paterson Orogen and is hosted by the Yeneena Supergroup, a 9 km thick sequence of marine sedimentary rocks. Gold and copper mineralization occurs in stratiform reefs and stockworks within the Malu Formation of the Lamil Group, controlled by both structure and lithology. Mineralisation styles include high-grade narrow reefs, reef stockwork corridors, sheeted vein sets, and extensive low-grade stockwork, which forms most of the sulphide resource. Sulphide mineralisation consists mainly of pyrite and chalcopyrite, with copper minerals including chalcopyrite, chalcocite, and bornite. Gold is primarily free-grained or associated with sulphides and quartz/dolomite gangue, with a correlation between vein density and gold grade. The highest gold and copper grades occur within bedding sub-parallel reef systems, including multiple reef structures in Main Dome, such as E-Reefs, MVR, M10-M70 reefs, A-Reef, and B-Reefs (notably B30). Additional mineralisation occurs in northwest-trending and north-dipping veins. Stockwork mineralisation, found in open pits, Telfer Deeps, and the Vertical Stockwork Corridor (VSC), is best developed in the axial zones of Main Dome and West Dome, often extending over large areas (0.1 km to 1.5 km). It can include brecciated zones filled with quartz, carbonate, and sulphides |

| Drill hole Information | Refer to Tables 1 and 2 - Significant Intercepts. |

| Data aggregation methods | Significant assay intercepts are reported using length-weighted averages based on predefined thresholds, with a maximum allowable internal dilution. For Open pit (RC) significant intercepts a maximum of 5m of internal dilution, minimum width of 3m, minimum grade of 0.5g/t and a gram metre (grade x length) of greater than 10gm. For Underground diamond significant intercepts a maximum of 5m of internal dilution, minimum width of 1m, minimum grade of 0.5g/t and a gram metre (grade x length) of greater than 10gm. |

| Relationship between mineralisation widths and intercept lengths | Significant assay intervals represent apparent widths, as drilling is not always perpendicular to the dip of mineralisation. True widths are typically less than downhole widths and can only be estimated once all results are received and final geological interpretations are completed. Where access permits all holes are drilled to intercept as close to true width as possible. |

| Diagrams | As provided |

| Balanced reporting | This is the second report released on the West Dome Underground by the Greatland group since taking ownership of the Telfer mine. Drilling results will be reported regularly and released to the market. Earlier reporting of exploration programs conducted by Newcrest and Greatland have previously been reported. Drilling programmes are ongoing and further material results will be reported in subsequent releases. |

| Other substantive exploration data | NIL |

| Further work | Drilling is ongoing with further work is planned to evaluate exploration opportunities that extend the known mineralisation. |

This information is provided by RNS, the news service of the London Stock Exchange. RNS is approved by the Financial Conduct Authority to act as a Primary Information Provider in the United Kingdom. Terms and conditions relating to the use and distribution of this information may apply. For further information, please contact [email protected] or visit www.rns.com.

RNS may use your IP address to confirm compliance with the terms and conditions, to analyse how you engage with the information contained in this communication, and to share such analysis on an anonymised basis with others as part of our commercial services. For further information about how RNS and the London Stock Exchange use the personal data you provide us, please see our Privacy Policy.

END

DRLQDLBLEFLEFBK