AI Terminal

EAST STAR RESOURCES PLC

Interim / Quarterly Report • Dec 31, 2025

5065_rns_2025-12-31_cf5277df-6acc-4c61-8fc8-b7f3db66d519.html

Interim / Quarterly Report

Open in ViewerOpens in native device viewer

National Storage Mechanism | Additional information ![]()

RNS Number : 2769N

East Star Resources PLC

31 December 2025

31 December 2025

East Star Resources Plc

("East Star" or the "Company")

VMS Drilling Update

Results from Verkhuba Confirm Deep Mineralisation

East Star Resources Plc (LSE:EST), the Kazakhstan-focused gold and base metals explorer, is pleased to provide an update on drilling activities which have been completed at the Verkhuba Copper Deposit ("Verkhuba"). Drilling aimed to test two important components of Verkhuba: deep resources defined by only historical drilling and shallow areas outside of the 2024 resource model.

Highlights

| · | Deep intervals of Zn-Cu mineralisation intersected |

| · | Shallow extension of mineralisation to the north |

| · | Confirm area of study for 2026 in JV with Hong Kong Xinhai Mining Services Limited ("Xinhai") |

Alex Walker, East Star CEO, commented:

"This drill programme was designed to test large distances between drill holes in the deeper part of the resource and a potential northern extension to the shallower part of the resource in the southwest. We intersected mineralisation at depth and an additional shallower ore lens, while also finding a continuation of the shallow mineralisation to the north. These are important results for the future study work at Verkhuba and have helped us to confirm the area of study for 2026 with Xinhai, who are farming into the project. These advances at Verkhuba will refine the deposit model and continue moving it closer to development. Lenses and stringer veinlets of sulphides logged in the core provide further evidence of massive sulphides at Verkhuba and we plan to test this in 2026 along with drilling the shallower resources with Xinhai to inform the feasibility study and mining licence application."

Deep Resource Confirmation

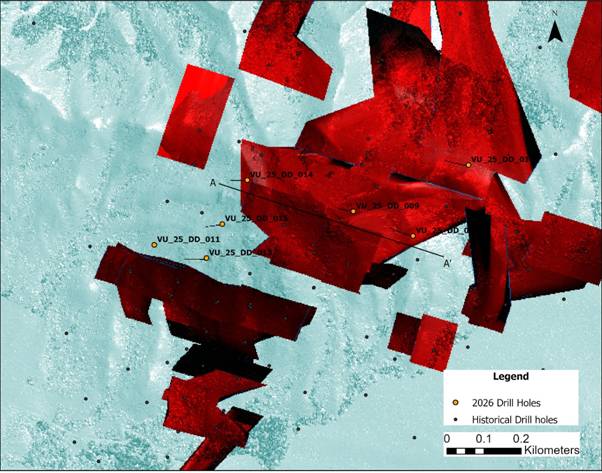

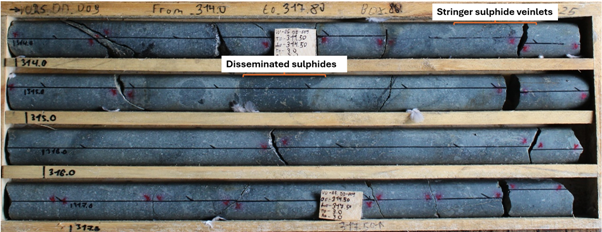

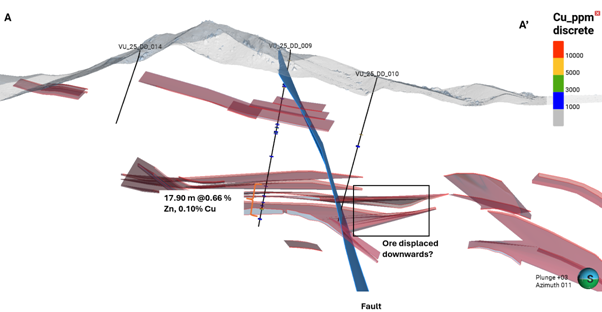

Three drill holes tested the deep resources (Figure 1). The holes intersected significant intervals of deeper Zn-Pb and Cu mineralisation. The mineralisation occurs within the major volcaniclastic unit as stringers and lenses of sulphide mineralisation (Figure 2). The drill holes infilled the drill spacing in the central deep ore body to ~120m (from ~200 - 250m spacing). Notably, additional shallow mineralisation was noted in drill hole VU_25_DD_009 at 75.5m. The drilling confirmed the thickness of the ore bodies in the central part of the ore body with VU_25_DD_009 containing 17.90m @ 0.66 % Zn and 0.10 % Cu from 307m.

The drilling also provided additional geological and structural information on the deposit. VU_25_DD_010 confirmed the presence of a fault cutting and displacing the ore body (Figure 3), demonstrating the requirement for more drilling into the parts of the resource with wider drill spacing.

| Hole_ID | From | To | Interval |

| VU_25_DD_009 | 75.5 | 76.5 | 1.00m @ 0.81 % Cu and 0.03 % Zn |

| VU_25_DD_009 | 293.7 | 294.8 | 1.10m @ 1.00 % Zn and 0.23 % Cu |

| VU_25_DD_009 | 297 | 299 | 2.00m @ 0.96 % Zn and 0.05 % Cu |

| VU_25_DD_009 | 307 | 324.9 | 17.90m @ 0.66 % Zn and 0.10 % Cu |

| VU_25_DD_009 | 329.1 | 333.5 | 4.40m @ 0.86 % Zn and 0.03 % Cu |

| VU_25_DD_011 | 74.5 | 76.5 | 2.00m @ 0.93 % Zn, 0.08 % Cu and 0.17 % Pb |

| VU_25_DD_012 | 31.1 | 32.5 | 1.40m @ 1.00 % Cu and 0.04 % Zn |

| VU_25_DD_012 | 110 | 112 | 2.00m @ 0.77 % Cu and 0.08 % Zn |

Figure 1: Plan view showing the Position of the holes drilled at Verkhuba during 2026

Figure 2: Lenses of disseminated sulphides in chlorite altered volcaniclastics, including sphalerite at 315 m

Figure 3: Section A-A' Deep resource drill holes confirm mineralisation and demonstrate faulting not accounted for in historical sections (image shows EST's interpretation, alternative geological explanations may apply)

Shallow Mineralisation

In addition to testing the deeper resources, East Star drilled four holes into the shallower resources. While disseminated sulphides were noted in these holes, only VU_25_DD_011 had significant mineralisation at 74.50 m containing 2.00m @ 0.93 % Zn, 0.08 % Cu and 0.17 % Pb. Additional geological information from drilling is required to understand the controls on the distribution of mineralisation in these shallow intervals.

Study Areas for 2026

The drilling completed in 2025 tested the possibility of extending the shallow resources and the continuity of the deeper resources. Drilling in 2026 will be part of the Joint Venture with Xinhai and will focus on the shallower resources. Additionally, East Star is planning a ground EM survey to test the potential for massive sulphides that have not yet been discovered.

East Star Resources Plc

Alex Walker, Chief Executive Officer

Tel: +44 (0)20 7390 0234 (via Vigo Consulting)

SI Capital (Corporate Broker)

Nick Emerson

Tel: +44 (0)1483 413 500

Vigo Consulting (Investor Relations)

Ben Simons / Peter Jacob

Tel: +44 (0)20 7390 0234

About East Star Resources Plc

East Star Resources is focused on the discovery and development of copper and gold in Kazakhstan. The Company is pursuing multiple exploration strategies including:

| · | A joint venture with Hong Kong Xinhai Mining Services Limited to take the Verkhuba Deposit (20.3Mt @ 1.16% copper, 1.54% zinc and 0.27% lead) into production (at no further cost to East Star) with East Star retaining 30% ownership in production |

| · | A second VMS Exploration Target with up to 23Mt @ 2.4% copper equivalent in the same region, with numerous other targets being advanced to drill-ready status |

| · | A $25 million+ strategic gold exploration joint venture with Endeavour Mining |

| · | Tier 1 potential copper porphyry targets and epithermal gold targets in a proven copper porphyry and epithermal belt |

Visit our website:

Follow us on social media:

LinkedIn: https://www.linkedin.com/company/east-star-resources/

X (formerly Twitter): https://twitter.com/EastStar_PLC

Subscribe to our email alert service to be notified whenever East Star releases news:

www.eaststarplc.com/newsalerts

The person who arranged for the release of this announcement was Alex Walker, CEO of the Company.

This announcement contains inside information for the purposes of Article 7 of Regulation 2014/596/EU which is part of domestic UK law pursuant to the Market Abuse (Amendment) (EU Exit) Regulations (SI 2019/310) ("UK MAR"). Upon the publication of this announcement, this inside information (as defined in UK MAR) is now considered to be in the public domain.

Competent Person Statement

Scientific or technical information in this disclosure related to exploration was reviewed by Dr Tremain Woods, a full-time employee of Discovery Ventures Kazakhstan Ltd, a 100% owned subsidiary of East Star Resources PLC. Dr Woods is a member in good standing with the Geological Society of South Africa. He has sufficient experience that is relevant to the commodity, style of mineralisation or type of deposit under consideration and activity which he is undertaking to qualify as a Competent Person under the JORC code (2012 Edition).

Table 1 Drill Results

Table 1a Drill Collars

| Hole_ID | Max Depth | NAT_East | NAT_North | NAT_RL | Azimuth | Dip | NAT_Grid_ID |

| VU_25_DD_009 | 356.5 | 603937 | 5591646 | 559 | 280 | -80 | WGS84_44N |

| VU_25_DD_010 | 295.3 | 604098 | 5591580 | 505 | 300 | -75 | WGS84_44N |

| VU_25_DD_011 | 149.7 | 603401 | 5591556 | 454 | 0 | -90 | WGS84_44N |

| VU_25_DD_012 | 295.1 | 604247 | 5591771 | 498 | 280 | -75 | WGS84_44N |

| VU_25_DD_013 | 197.5 | 603541 | 5591520 | 488 | 280 | -80 | WGS84_44N |

| VU_25_DD_014 | 152.5 | 603651 | 5591730 | 556 | 280 | -80 | WGS84_44N |

| VU_25_DD_015 | 150.6 | 603584 | 5591612 | 556 | 280 | -80 | WGS84_44N |

Table 1b Significant Intercepts

| Hole_ID | Depth From | Depth To | Intercept Description |

| VU_25_DD_009 | 75.5 | 76.5 | 1.00m @ 0.81 % Cu; 0.00 % Pb; 0.03 % Zn |

| VU_25_DD_009 | 166.2 | 167.2 | 1.00m @ 0.35 % Cu; 0.00 % Pb; 0.01 % Zn |

| VU_25_DD_009 | 320 | 322 | 2.00m @ 0.53 % Cu; 0.00 % Pb; 0.57 % Zn |

| VU_25_DD_012 | 31.1 | 32.5 | 1.40m @ 1.00 % Cu; 0.00 % Pb; 0.04 % Zn |

| VU_25_DD_012 | 110 | 112 | 2.00m @ 0.77 % Cu; 0.00 % Pb; 0.08 % Zn |

| VU_25_DD_012 | 170 | 172 | 2.00m @ 0.38 % Cu; 0.00 % Pb; 0.02 % Zn |

| VU_25_DD_012 | 236 | 240 | 4.00m @ 0.24 % Cu; 0.01 % Pb; 0.76 % Zn |

| VU_25_DD_012 | 251 | 252 | 1.00m @ 0.32 % Cu; 0.00 % Pb; 0.01 % Zn |

| VU_25_DD_009 | 293.7 | 294.8 | 1.10m @ 1.00 % Zn; 0.23 % Cu; 0.00 % Pb |

| VU_25_DD_009 | 297 | 299 | 2.00m @ 0.96 % Zn; 0.05 % Cu; 0.00 % Pb |

| VU_25_DD_009 | 307 | 324.9 | 17.90m @ 0.66 % Zn; 0.10 % Cu; 0.00 % Pb |

| VU_25_DD_009 | 329.1 | 333.5 | 4.40m @ 0.86 % Zn; 0.03 % Cu; 0.00 % Pb |

| VU_25_DD_010 | 219 | 221 | 2.00m @ 0.51 % Zn; 0.02 % Cu; 0.34 % Pb |

| VU_25_DD_011 | 65 | 66.5 | 1.50m @ 0.60 % Zn; 0.18 % Cu; 0.06 % Pb |

| VU_25_DD_011 | 74.5 | 76.5 | 2.00m @ 0.93 % Zn; 0.08 % Cu; 0.17 % Pb |

| VU_25_DD_012 | 233 | 247 | 14.00m @ 0.60 % Zn; 0.08 % Cu; 0.00 % Pb |

| VU_25_DD_012 | 250 | 251 | 1.00m @ 0.76 % Zn; 0.02 % Cu; 0.00 % Pb |

| VU_25_DD_010 | 219 | 221 | 2.00m @ 0.34 % Pb; 0.02 % Cu; 0.51 % Zn |

Table 2 - JORC Code, 2012 Edition

Section 1 Sampling Techniques and Data

Criteria

JORC Code explanation

Commentary

Sampling techniques

· Nature and quality of sampling (e.g. cut channels, random chips, or specific specialised industry standard measurement tools appropriate to the minerals under investigation, such as down hole gamma sondes, or handheld XRF instruments, etc). These examples should not be taken as limiting the broad meaning of sampling.

· Include reference to measures taken to ensure sample representivity and the appropriate calibration of any measurement tools or systems used.

· Aspects of the determination of mineralisation that are Material to the Public Report.

· In cases where 'industry standard' work has been done this would be relatively simple (e.g. 'reverse circulation drilling was used to obtain 1 m samples from which 3 kg was pulverised to produce a 30 g charge for fire assay'). In other cases, more explanation may be required, such as where there is coarse gold that has inherent sampling problems. Unusual commodities or mineralisation types (e.g. submarine nodules) may warrant disclosure of detailed information.

· Samples were taken from half drill core through sulphide or oxide mineralised intervals.

· Sampling was conducted through mineralized intervals, with samples taken 2 meters into the hanging wall and footwall for intervals larger than 3 meters. For smaller intervals (<2 meters), only the mineralized portion is sampled.

· Sample quality is ensured by a structured scheme, including blanks, certified reference materials (CRM), and duplicates.

· Banks are inserted at the beginning and end of large, mineralized intervals, but not for smaller isolated intervals.

· CRMs are inserted at every 50th and 100th sample to monitor consistency.

· Coarse duplicates are taken every 40th and 80th sample, focused on mineralized portions, and 5% of mineralized pulps are sent for external lab analysis.

· A total of 1407.60 meters of core were sampled (of a total of 1597.20 m drilled), with 733 core samples collected, including 48 blanks, 20 CRMs, and 27 duplicate samples.

· Core samples were prepared by ALS Kazgeochemistry LLP, using standard methods like crushing, sieving (<70% passing 2mm), and milling (>85% passing 75μm).

· Samples are analysed using the ME-ICP41 method for routine analysis, and for over-limit ore samples, the ME-OG62 method is used.

Drilling techniques

· Drill type (e.g. core, reverse circulation, open-hole hammer, rotary air blast, auger, Bangka, sonic, etc) and details (e.g. core diameter, triple or standard tube, depth of diamond tails, face-sampling bit or other type, whether core is oriented and if so, by what method, etc).

· Drilling was conducted using stand HQ sized diamond drilling technique.

· Positive Group Kazakhstan undertook drilling.

· Drill core was orientated using a REFLEX Act III orientation tool. All holes that weren't drilled vertically were orientated once solid core was intersected.

· After drilling was completed, all holes were survey at 50 m intervals using the REFLEX EZ TRAC survey tool

Drill sample recovery

· Method of recording and assessing core and chip sample recoveries and results assessed.

· Measures taken to maximise sample recovery and ensure representative nature of the samples.

· Whether a relationship exists between sample recovery and grade and whether sample bias may have occurred due to preferential loss/gain of fine/coarse material.

· Core recovery was measured by East Star geologists, an average of 96 % recovery was recorded for the three completed drill holes.

· Through the mineralized intervals, core recovery was 97% and greater.

· There is no relationship between Cu, Pb or Zn grades and recovery.

· There does not appear to have been any bias due to sample material loss/grain

Logging

· Whether core and chip samples have been geologically and geotechnically logged to a level of detail to support appropriate Mineral Resource estimation, mining studies and metallurgical studies.

· Whether logging is qualitative or quantitative in nature. Core (or costean, channel, etc) photography.

· The total length and percentage of the relevant intersections logged.

· East Star geologists undertook core logging.

· Quantitative data for mineralization, lithology, structure, alteration, oxidation, and weathering was logged.

· All recovered core was logged and photographed before and after sampling

Sub-sampling techniques and sample preparation

· If core, whether cut or sawn and whether quarter, half or all core taken.

· If non-core, whether riffled, tube sampled, rotary split, etc and whether sampled wet or dry.

· For all sample types, the nature, quality, and appropriateness of the sample preparation technique.

· Quality control procedures adopted for all sub-sampling stages to maximise representivity of samples.

· Measures taken to ensure that the sampling is representative of the in-situ material collected, including for instance results for field duplicate/second-half sampling.

· Whether sample sizes are appropriate to the grain size of the material being sampled.

· Half core samples were collected for processing, the remaining half core is securely stored at East Star's core storage facilities in Verkhuba Village

· Samples were crushed into chips; the chips were passed through a riffle splitter several times to obtain 500 g samples for milling. Crushed sample duplicates were analysed to confirm homogeneity of crushed samples.

· Blank granite material was also inserted into the sample stream to ensure no contamination occurs during crushing or milling.

· ALS laboratories weigh samples before and after sieving, to ensure that the thresholds for size fractions are met for each sample.

Quality of assay data and laboratory tests

· The nature, quality and appropriateness of the assaying and laboratory procedures used and whether the technique is considered partial or total.

· For geophysical tools, spectrometers, handheld XRF instruments, etc, the parameters used in determining the analysis including instrument make and model, reading times, calibrations factors applied and their derivation, etc.

· Nature of quality control procedures adopted (e.g. standards, blanks, duplicates, external laboratory checks) and whether acceptable levels of accuracy (i.e. lack of bias) and precision have been established.

· Aqua regia is a partial digest method well suited to base metal analyses, the method at ALS is internationally recognized and provides precise and accurate analyses.

· Standard assay quality controls are used by the laboratory and East Star inserted QA/QC samples to evaluate and confirm the assay results. All QA/QC samples reported within limits.

Verification of sampling and assaying

· The verification of significant intersections by either independent or alternative company personnel.

· The use of twinned holes.

· Documentation of primary data, data entry procedures, data verification, data storage (physical and electronic) protocols.

· Discuss any adjustment to assay data.

· Significant intersections were confirmed visually by East Star's exploration manager, no independent verification has been completed to date.

· Logged data was inspected by East Star's exploration manager, any changes to the logged data were made before data was sent to Rock Solid based in Perth, Australia to be added to the maintained SQL database

Location of data points

· Accuracy and quality of surveys used to locate drill holes (collar and down-hole surveys), trenches, mine workings and other locations used in Mineral Resource estimation.

· Specification of the grid system used.

· Quality and adequacy of topographic control.

· Drill holes were surveyed using Garmin GPSMAP 62S handheld GPS device. DGPS surveys are planned once all drilling is completed.

· Grid system WGS83, UTM44N

· Some errors were noted in the elevation readings (from 5 - 14 m errors), these were adjusted to the elevation values of the LIDAR topography survey at the coordinates of the drill hole.

· A drone LIDAR survey was conducted in 2023. The survey conducted by Aurora Geophysics used a drone mounted LIDAR sensor (DJI Zenmuse L1 Lidar on a DJI Matrice 300 RTK Combo D-RTK 2 drone) with a base station (Trimble R12 and Trimble TDL 450 radio modem). Flight lines were 90 m apart, and the resolution produced was 3.44 cm/pixel. The processed digital terrane model was checked against control points.

Data spacing and distribution

· Data spacing for reporting of Exploration Results.

· Whether the data spacing and distribution is sufficient to establish the degree of geological and grade continuity appropriate for the Mineral Resource and Ore Reserve estimation procedure(s) and classifications applied.

· Whether sample compositing has been applied.

· Historical drilling was drilled along NW-SE trending lines, the lines were spaced between 200-300m apart and drill holes were spaced between 100 and 250 m apart.

· Current drilling aims to infill the spacing to ~120m.

· The current drill holes have reduced the spacing within the Ultimate Open Pit generated by AMC in April 2024 to ~100m.

· Geological distribution is sufficient for inferred resources throughout the ultimate pit shell (from April 2024). Some parts have sufficient spacing to be classified as indicated resources.

· Significant intercepts are reported for results from 2024 drilling using the following parameters:

| Parameter | Report 1 | Report 2 | Report 3 |

| Element | Cu | Zn | Pb |

| Min Cut-off Grade % | 01% | 0.1% | 0.1% |

| Max Cut-off Grade % | n/a | n/a | n/a |

| Min Intercept Length (metres) | n/a | 2m | n/a |

| Maximum Consecutive Internal Waste (m) | 2m | 2m | 2m |

| Minimum Intercept Grade % | n/a | All (no filter) | All (no filter) |

| Co-elements in report | Pb, Zn | Pb, Zn | Cu, Zn |

·

Orientation of data in relation to geological structure

· Whether the orientation of sampling achieves unbiased sampling of possible structures and the extent to which this is known, considering the deposit type.

· If the relationship between the drilling orientation and the orientation of key mineralized structures is considered to have introduced a sampling bias, this should be assessed and reported if material.

· Sampling is taken for all intervals with sulphide mineralization.

· Sampling adhered to lithological boundaries and additionally the hanging wall and footwall was sampled.

· The ore body generally dips 30 to 40 to the SW. In some parts of the deposit the ore body dips steeper 80. These steeper areas of mineralization are interpreted to be the result of post mineralization deformation.

· The ore body is cut by steep NE faults, these normal faults are interpreted to throw the lower ore body 20-40 m

Sample security

· The measures taken to ensure sample security.

· After samples are cut and bagged, they are sealed with zip ties. Samples were taken by East Star's senior geologist to ALS Oskemen.

· The samples remained sealed until handed over to the laboratory.

· Samples in the laboratory follow ALS standard procedures to ensure sample security.

Audits or reviews

· The results of any audits or reviews of sampling techniques and data.

· No audits were undertaken for this phase of sampling.

· The sample methodology was checked and confirmed by the Competent Person for the AMC MRE (April 2024)

Section 2 Reporting of Exploration Results

Criteria

JORC Code explanation

Commentary

Mineral tenement and land tenure status

· Type, reference name/number, location and ownership including agreements or material issues with third parties such as joint ventures, partnerships, overriding royalties, native title interests, historical sites, wilderness or national park and environmental settings.

· The security of the tenure held at the time of reporting along with any known impediments to obtaining a licence to operate in the area.

· The Verkhuba polymetallic deposit is located in the eastern part of exploration license 1795-EL (the "License"). The license was issued to Discovery Ventures Kazakhstan Limited (the "DVK") on 27 July 2022 for initial period of 6 years with a possibility of further five years extension subject to reduction of the license area by 40%.

· East Star resources have servitude for exploration from the local Akim (administrative head), the license can be explored under these agreements.

· There are no known legal or security impediments to obtaining a mining license

Exploration done by other parties

· Acknowledgment and appraisal of exploration by other parties.

· Table of previously completed exploration

| Principal author, year | Period | Exploration | Results |

|---|---|---|---|

| Yakovlev et al., 1950 | 1948-1950 | Geological mapping | Geological map 1:10,000 |

| Krysova et al., 1954 | 1953-1954 | Geological mapping | Geological map 1:10,000 |

| Yusupov et al., 1956 | 1956 | Geological traverses, core drilling | Potential of oxidation zone |

| Anoshin et al., 1972 | 1971-1972 | Geological, geochemical survey, shallow prospecting shafts and drilling, ground IP, EM, magnetics, core drilling | Follow-up targets, discovery of new mineralized zones at depth |

| Rodionov, Gorelova, 1976 | 1974-1976 | Geological traverses, deep drilling | Follow-up targets, prognostic resources |

| Avdonin et al., 1977 | 1974-1977 | Mapping of Devonian volcanic centres | Follow-up targets, maps of distal and proximal volcanic facies |

| Nazarov, San'kov, 1986 | 1982-1986 | Geological mapping at scale 1:50,000, ground IP, EM, magnetics, diamond drilling on the anomalies | Prognostic resources |

| Radchenko et al., 1987 | 1985-1987 | Grid drilling 800-400 x 400-200 m, geochemical sampling, ground IP, EM, magnetics | Follow-up targets, tracing of mineralization |

| Grigorovich et al., 1990 | 1986-1988 | Infill diamond drilling 200 x 400, 100 x 200, 75 x 100-180 m, underground development (an adit and drives) totalling 3001 m, metallurgical testing | Completion of drilling database of the Verkhuba deposit for follow-up MRE |

| Ermolaev et al., 1990 | 1990 | Technical economic consideration of Verkhuba deposit | Mineral resource estimate in P1-C2 categories (GKZ) |

| ESR | 2023 | Exploration Target estimate | Exploration Target estimate report (JORC) |

| ESR | 2024 | Drilling of six verification and in-fill holes, topography survey, development of lithological model | MRE report |

Geology

· Deposit type, geological setting, and style of mineralisation.

· Verkhuba is Volcanogenic Massive Sulphide (VMS) deposit. Historical reports indicate that the type is felsic bimodal (or Kuroko-type).

· The mineralization is lenticular massive and disseminated sulphides hosted in volcaniclastic units sub horizontal units.

· Mineralisation occurs as a copper rich unit at shallower depths (<150 m) and a zinc-copper unit deeper (~200m)

· The area has seen post depositional deformation in the form of folding and faulting

Drill hole Information

· A summary of all information material to the understanding of the exploration results including a tabulation of the following information for all Material drill holes:

o easting and northing of the drill hole collar

o elevation or RL (Reduced Level - elevation above sea level in metres) of the drill hole collar

o dip and azimuth of the hole

o down hole length and interception depth

o hole length.

· If the exclusion of this information is justified on the basis that the information is not Material and this exclusion does not detract from the understanding of the report, the Competent Person should clearly explain why this is the case.

· Drill hole information: see table 1a

· Significant intercepts: see table 1b

· No material information has been excluded from this report

Data aggregation methods

· In reporting Exploration Results, weighting averaging techniques, maximum and/or minimum grade truncations (e.g. cutting of high grades) and cut-off grades are usually Material and should be stated.

· Where aggregate intercepts incorporate short lengths of high-grade results and longer lengths of low-grade results, the procedure used for such aggregation should be stated and some typical examples of such aggregations should be shown in detail.

· The assumptions used for any reporting of metal equivalent values should be clearly stated.

· Samples were composited by ALS Geochemistry by combining split samples of individual meter samples into a single composite sample, homogenised and then an aliquot was taken for sample analysis.

· No metal equivalents are reported.

· Results for 32 elements received, but only Cu, Pb Zn is reported.

Relationship between mineralisation widths and intercept lengths

· These relationships are particularly important in the reporting of Exploration Results.

· If the geometry of the mineralisation with respect to the drill hole angle is known, its nature should be reported.

· If it is not known and only the down hole lengths are reported, there should be a clear statement to this effect (e.g. 'down hole length, true width not known').

· The ore bodies are generally concordant to lithology (perpendicular to core axis). At some depths mineralization occurs as steeply dipping veins and veinlets with limited extent (low angles to core axis).

· Drill holes were planned at 65 - 70° towards the north to intercept mineralisation at perpendicular angles. Mineralisation is typically sub-horizontal in core indicating that the true thickness is ~90% of the thickness of intervals in core. Therefore, one can assume that intervals thickness are as drilled.

Diagrams

· Appropriate maps and sections (with scales) and tabulations of intercepts should be included for any significant discovery being reported These should include but not be limited to a plan view of drill hole collar locations and appropriate sectional views.

· Relevant diagrams have been included in the body text

Balanced reporting

· Where comprehensive reporting of all Exploration Results is not practical, representative reporting of both low and high grades and/or widths should be practiced to avoid misleading reporting of Exploration Results.

· Grades below the cut off parameters have not been reported with these results. However, the mineralization has been noted within East Star's models and will inform future estimates

Other substantive exploration data

· Other exploration data, if meaningful and material, should be reported including (but not limited to): geological observations; geophysical survey results; geochemical survey results; bulk samples - size and method of treatment; metallurgical test results; bulk density, groundwater, geotechnical and rock characteristics; potential deleterious or contaminating substances.

· Not applicable

Further work

· The nature and scale of planned further work (e.g. tests for lateral extensions or depth extensions or large-scale step-out drilling).

· Diagrams clearly highlighting the areas of possible extensions, including the main geological interpretations and future drilling areas, provided this information is not commercially sensitive.

· Further drilling is planned in 2026, however the amount and locations have not been determined yet

· A ground EM survey over the Verkhuba Deposit is planned

This information is provided by RNS, the news service of the London Stock Exchange. RNS is approved by the Financial Conduct Authority to act as a Primary Information Provider in the United Kingdom. Terms and conditions relating to the use and distribution of this information may apply. For further information, please contact [email protected] or visit www.rns.com.

RNS may use your IP address to confirm compliance with the terms and conditions, to analyse how you engage with the information contained in this communication, and to share such analysis on an anonymised basis with others as part of our commercial services. For further information about how RNS and the London Stock Exchange use the personal data you provide us, please see our Privacy Policy.

END

DRLWPGWAPUPAUQG